Industrial seals

Seals have a crucial impact on system performance. Life and reliability of what is often considered a simple component can make all the difference to your product and operations. With SKF, you get support for all the key aspects of your sealing system.

For the last 110+ years, CR Seals has been setting performance and service life standards for industrial and automotive shaft seals. CR Seals has also been part of SKF since 1990, a span during which we’ve developed new materials, manufacturing processes and designs to create some of the most robust seals on the market.

Power Transmission Seals

SKF’s offer of radial and axial shaft sealing solutions for power transmission applications supports virtually every industrial sector, from large-size wind turbines to very small, high-speed machine tools. For off-highway applications, we offer undercarriage sealing solutions for wheeled equipment, which include SKF Mud block cassette seals and the innovative SKF Track star seals for tracked machinery.

Radial shaft seals: static and dynamic performance

Radial shaft seals sit between rotating and stationary components, or two components in relative motion. They have two main parts. One is a cylindrical outer covering with an interference fit that seals statically against the housing bore. The second, a sealing lip, seals dynamically and statically against the shaft. Its sealing edge presses against the counterface surface of the shaft with a defined radial load.

Wear sleeves

To seal efficiently, radial shaft seals must run against a smooth, round counterface. If the counterface becomes worn, the seals will no longer be able to fulfill their function, which is to retain lubricant and exclude contaminants.

Typically, the counterface becomes scored when a contaminant particle is caught under the sealing lip and abrades a track as the shaft rotates. As this continues, the seal will enable more particles to pass or get stuck, and seal efficiency deteriorates, eventually leading to malfunction of the component that the seal is meant to protect. To rectify the situation, it is necessary to repair the shaft surface since a seal replacement will not be sufficient. To repair the shaft, it is usually necessary to disassemble the machine in order to either replace the shaft or grind down the counterface until it is again within specification.

SKF Speedi-Sleeve (fig 1) is a well-proven solution to overcome problems with worn shafts without having to disassemble the shaft or changing the seal dimensions, while offering an excellent sealing surface. Now, SKF has developed a new generation SKF Speedi-Sleeve with features providing an even further enhanced sealing system performance. Using SKF Speedi-Sleeve, combined with an SKF radial shaft seal, customers will benefit from a more consistent and increased durability of the sealing system. This will enable a more stable maintenance planning with improved predictability of the system service life. SKF Speedi-Sleeve is available for shaft diameters up to approximately 203 mm (8 in.). For larger shaft diameters, SKF offers wear sleeves for heavy industrial applications (fig 2).

If the shaft cannot be ground and hardened as a seal counterface or if a replaceable seal counterface is required, needle roller bearing inner rings with non-directionally ground raceway (designation IR .. EGS) can be used (fig 3).

V-ring seals

V-ring seals are axial shaft seals, available in a wide range of sizes and appropriate for many applications. SKF supplies two types of V-ring seals:

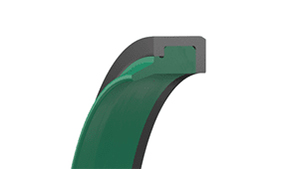

All-rubber V-rings (fig 1), or just called "V-rings"

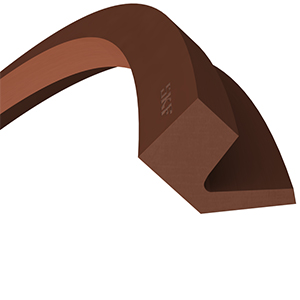

MVR axial shaft seals (fig 2), a metal-cased V-ring seal

Hydraulic seals

- Hydraulic seals are used hydraulic in cylinders to seal the openings between various components in the hydraulic cylinder.

- Seals are either moulded or machined and are carefully designed using sophisticated simulation software.

- Products perform both dynamic and static sealing. The range includes piston, rod, buffer and wiper seals, as well as guide rings and O-rings.

Piston seals

Piston seals maintain sealing contact between a piston and cylinder bore. The moving piston rod generates high pressure on the piston seal which increases contact forces between the seal and cylinder surface. For this reason, the surface properties of the sealing surfaces are critical to proper seal performance.

Rod and buffer seals

Rod and buffer seals maintain sealing contact in sliding motion between the cylinder head and the piston rod. Depending on the application, a rod sealing system can consist of a rod seal and a buffer seal ( fig. 1) or a rod seal only ( fig. 2). Rod sealing systems for heavy duty applications typically consist of a combination of both seal types, whereas the buffer seal is arranged between the rod seal and the piston in the cylinder head. Rod seals determine the tolerance for the rod diameter d.

In addition to the sealing function, rod seals also provide a thin lubrication film on the piston rod that lubricates themselves and the wiper seals. The lubricant also inhibits corrosion of the piston rod surface. However, the lubrication film must be thin enough so that it returns to the cylinder during the return stroke.

Selecting profiles and materials for a rod sealing system is a complex task, considering all possible cylinder designs and application criteria. SKF supplies rod and buffer seals in many different profiles and in a wide range of materials, series and sizes, which make them appropriate for a wide variety of operating conditions and applications.

Wiper seals

Hydraulic cylinders operate in a variety of applications and environmental conditions, including exposure to dust, debris or outside weather conditions. To prevent these contaminants from entering the cylinder assembly and hydraulic system, wiper seals (also known as scrapers, excluders or dust seals) are fitted on the external side of the cylinder head (fig. 1).

Wiper seals maintain sealing contact to the piston rod when the equipment is stationary (static, no reciprocating motion of rod) and in use (dynamic, reciprocating rod), whereas the tolerance for the rod diameter d is determined by the rod seal. Without a wiper seal, the retracting piston rod could transport contaminants into the cylinder.

The outside static sealing of the wiper seal within the housing is also important to avoid moisture or particles from entering around the outside of the wiper seal.

O-rings and back-up rings

O-rings are one of the most common sealing solutions. SKF supplies O-rings in a wide range of sizes and different materials, which make them appropriate for a wide variety of operating conditions and applications. They are easy to install and they enable a simple and cost-effective seal housing design.

O-rings maintain sealing contact force by radial or axial deformation in the seal housing between two machine components. The most important criteria that influence the maximum operating pressure at which O-rings in static radial sealing can be used are the following:

Dimensions and performance data are provided in the data tables:

- Extrusion gap (fig. 1)

- Material (→ Materials)

- Sealed fluid

- Temperature

Under specific conditions, there is a risk for gap extrusion (→ Extrusion gaps and back-up rings). Back-up rings prevent O-rings from gap extrusion in static radial sealing (fig. 1).

O-rings are used in a wide variety of applications sealing various media. This section focuses on sealing systems for hydraulic cylinders. Therefore, this section and provided recommendations apply to static sealing of common mineral-based hydraulic fluids (→ Hydraulic fluids).

Machined seals

SKF is the global market and technology leader in high quality custom engineered sealing solutions offering a comprehensive range of machined seals for many industries.

The innovative production system - SKF SEAL JET - reduces manufacturing and dispatch time to a minimum. Virtually any kind of seal for any conceivable application, in any dimension and design, can be produced.

SKF offers machined sealing solutions for fluid power, fluid handling and power transmission applications including special large diameter seals with a virtually unlimited diameter range.