Lincoln

Lincoln is the world leader in the manufacturing and sale of lubrication and pumping equipment for industry. Founded in 1993, the company is based in Bengaluru, India.

As of 2010 Lincoln Helios is a part of SKF. Lincoln is an SKF Group brand.

Lubrication solutions

Poor lubrication causes about 36% of all premature bearing failures

But with the right lubrication solution you can create new opportunities to increase uptime and productivity. Along with helping to reduce premature bearing failures and machine downtime, proper lubrication can increase energy efficiency. At SKF, we can help you realize the true potential of lubrication.

SKF lubrication solutions range from specialized lubricants to state-of-the-art lubrication systems. Integrated SKF lubrication solutions combine our expertise in bearings, seals and condition monitoring with our tribology knowledge – the study of friction, wear and lubrication.

You can also count on leading technical support and services. This includes lubrication management programmes to help with lubricant selection, planning and monitoring – all from a single, reliable partner.

Lincoln Helios (India) Ltd. designs, manufactures and supplies lubrication products and systems in India. Its range of product offerings include

- Single-line lubrication systems

- Dual-line lubrication systems

- Progressive lubrication systems

- Multi-line lubrication systems

- Small oil circulation systems

- Oil and air lubrication systems

- Ink transfer systems

- Minimal quantity lubrication systems

- Chain lubrication systems

Right from steel, cement, power, mining, earth moving to sugar, tires, glass, paper, food and beverages and automobiles, Lincoln Helios caters to the lubrication requirements of various major industries. The company’s services include installation and commissioning support for the lubrication systems, post-sales service support, training and seminars and annual maintenance contracts.

Lincoln offers the widest range of lubrication products, which can be tailored to give our customers the most cost-effective lubrication solutions their application.

Automatic lubrication systems

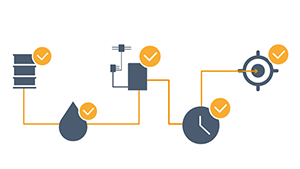

The right lubricant, in the right quantity, at the right time, to the right lubrication point

Centralized automatic lubrication systems are an effective way to increase machine availability while reducing reliance on scarce talent. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and machinery service life.

Designed to lubricate individual machines or complete plants, automatic lubrication systems provide proper, precise lubricant replenishment to all required points, enabling a range of benefits in the process.

Lubrication pumps and pump units

Lubrication pumps feed lubricant from the lubricant reservoir into the tubing system of the automatic centralized lubrication system. The manometric pressure has to be high enough to compensate for pressure drops in the tubing, components (filters, valves, distributors) and friction points.

Lubricant metering devices

Lubricant metering devices deliver preset lubricant dosages to lubrication points or measure lubricant out to lubrication points over a specified period of time.

Monitoring devices for use with lubrication systems

Various devices that generate a visual or electrical signal can be used for this purpose. These signals are analyzed by the electronic control and monitoring devices and provide appropriate information to the machine's control unit or operator.

Accessories for lubrication systems

With the right fittings and accessories you can complete your lubrication system. The right applicator like nozzles, brushes or pinions can help to fulfill specific lubrication tasks.

Couplings

Power transmission couplings that meet your specific requirements

Machine designers are under pressure to raise the performance of power transmission systems, in the face of diminishing time and resources.

A diversity of coupling systems, including customised products, helps these systems work effectively and efficiently. Factors such as size and torque requirements determine the most appropriate coupling to use.

We offer all the main types, including grid, gear, flex and jaw couplings. In addition we supply OK couplings, which use oil injection for mounting and dismounting, and flexible shaft couplings.

Flexible shaft couplings compensate for four types of shaft misalignment: angular, offset, a combination of the two, and axial movement. Grid couplings are aimed at high output, high torque gear applications, while gear couplings are heavy duty products with large bore capacities.

Most products are made from cast iron, though some (such as chain couplings) use carbon steel. Surface treatment techniques, including phosphate coating, help to protect against corrosion.

Our whole range of couplings can be searched and specified by clicking the ‘Online Catalogue’ button and choosing a product from the drop-down menu.