Lubrication management

For every industry, lubrication is vital to the performance of rotating equipment; when over 40% of maintenance cost are related to poor lubrication, proper management is crucial. The right quantity of the right lubricant applied at the right intervals is essential to achieving optimum application performance and maximum service life.

Together, SKF and Lincoln combine more than 300 years of experience in managing lubrication and reducing friction. And with our pioneering RecondOil process technology for uncompromised industrial oil regeneration, you can reuse your oil over and over again.

No matter where in the lubrication management journey you are, with SKF you can boost the performance that matters to your business. Find out how.

Lubricants

Poor lubrication accounts for over 36% of premature bearing failures

SKF lubricants are designed for your needs and tested for performance in real applications. Our experience with bearings, lubricants and applications helps us to offer the right lubricants for your applications and improve your overall lubrication scheme.

Testing and validating each production batch is our way to offer excellent lubricant quality around the globe.

Specialized lubricant tests and continuous research in the field of lubrication allows SKF to further optimize our knowledge and support you with right lubrication for your machines.

SKF lubricants offer major advantages:

- Designed and tested to perform under real conditions

- Global availability with consistent quality

- Better lubricant selection with specific test results included in lubricant specifications

- Strict quality control of every production batch helps ensure reliable performance

Manual lubrication tools

The right lubrication is essential for machine performance and reliable operation

The right lubricant has to be supplied in the right quantity at the right time in the right quality to the right location. Particularly contamination during the transfer process, applying too much or too little lubricant and using the wrong lubricant for a lubrication point are common problems and can easily be prevented. The SKF manual lubrication tools are specifically designed and selected to support these processes with a wide product portfolio for lubricant storage, handling, dosing, labelling, analyzing and applying lubricants.

Benefits of manual lubrication tools

- Avoid mistakes during manual lubrication with tools that are designed to support the “right” lubrication

- Select the best products for your needs from a wide product portfolio for storage, handling, dosing, labelling, analyzing and applying lubricants

Lubricators

Automatic lubricators are installed on single lubrication points and automatically dispense the proper amount of lubricant to the application. Especially when lubrication points are difficult to access for safety reasons or their location in the plant, automatic lubricators can offer the solution. A wide range of single point automatic lubricators and accessories offers a solution for most lubrication points. Utilizing automatic lubricators helps to improve worker safety, maintenance efficiency and machine reliability.

Benefits of automatic lubricators

- Increase worker safety for lubrication of difficult to access lubrication points

- Support maintenance efficiency with automated lubricant supply

- Improve machine reliability with optimized lubricant supply

- Select the right lubricators type and lubricant for your needs from a wide portfolio

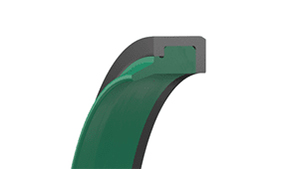

Hydraulic seals

- Hydraulic seals are used hydraulic in cylinders to seal the openings between various components in the hydraulic cylinder.

- Seals are either moulded or machined and are carefully designed using sophisticated simulation software.

- Products perform both dynamic and static sealing. The range includes piston, rod, buffer and wiper seals, as well as guide rings and O-rings.

Piston seals

Piston seals maintain sealing contact between a piston and cylinder bore. The moving piston rod generates high pressure on the piston seal which increases contact forces between the seal and cylinder surface. For this reason, the surface properties of the sealing surfaces are critical to proper seal performance.

Rod and buffer seals

Rod and buffer seals maintain sealing contact in sliding motion between the cylinder head and the piston rod. Depending on the application, a rod sealing system can consist of a rod seal and a buffer seal ( fig. 1) or a rod seal only ( fig. 2). Rod sealing systems for heavy duty applications typically consist of a combination of both seal types, whereas the buffer seal is arranged between the rod seal and the piston in the cylinder head. Rod seals determine the tolerance for the rod diameter d.

In addition to the sealing function, rod seals also provide a thin lubrication film on the piston rod that lubricates themselves and the wiper seals. The lubricant also inhibits corrosion of the piston rod surface. However, the lubrication film must be thin enough so that it returns to the cylinder during the return stroke.

Selecting profiles and materials for a rod sealing system is a complex task, considering all possible cylinder designs and application criteria. SKF supplies rod and buffer seals in many different profiles and in a wide range of materials, series and sizes, which make them appropriate for a wide variety of operating conditions and applications.

Wiper seals

Hydraulic cylinders operate in a variety of applications and environmental conditions, including exposure to dust, debris or outside weather conditions. To prevent these contaminants from entering the cylinder assembly and hydraulic system, wiper seals (also known as scrapers, excluders or dust seals) are fitted on the external side of the cylinder head (fig. 1).

Wiper seals maintain sealing contact to the piston rod when the equipment is stationary (static, no reciprocating motion of rod) and in use (dynamic, reciprocating rod), whereas the tolerance for the rod diameter d is determined by the rod seal. Without a wiper seal, the retracting piston rod could transport contaminants into the cylinder.

The outside static sealing of the wiper seal within the housing is also important to avoid moisture or particles from entering around the outside of the wiper seal.

O-rings and back-up rings

O-rings are one of the most common sealing solutions. SKF supplies O-rings in a wide range of sizes and different materials, which make them appropriate for a wide variety of operating conditions and applications. They are easy to install and they enable a simple and cost-effective seal housing design.

O-rings maintain sealing contact force by radial or axial deformation in the seal housing between two machine components. The most important criteria that influence the maximum operating pressure at which O-rings in static radial sealing can be used are the following:

Dimensions and performance data are provided in the data tables:

- Extrusion gap (fig. 1)

- Material (→ Materials)

- Sealed fluid

- Temperature

Under specific conditions, there is a risk for gap extrusion (→ Extrusion gaps and back-up rings). Back-up rings prevent O-rings from gap extrusion in static radial sealing (fig. 1).

O-rings are used in a wide variety of applications sealing various media. This section focuses on sealing systems for hydraulic cylinders. Therefore, this section and provided recommendations apply to static sealing of common mineral-based hydraulic fluids (→ Hydraulic fluids).

Machined seals

SKF is the global market and technology leader in high quality custom engineered sealing solutions offering a comprehensive range of machined seals for many industries.

The innovative production system - SKF SEAL JET - reduces manufacturing and dispatch time to a minimum. Virtually any kind of seal for any conceivable application, in any dimension and design, can be produced.

SKF offers machined sealing solutions for fluid power, fluid handling and power transmission applications including special large diameter seals with a virtually unlimited diameter range.