Maintenance Products

Every bearing has a certain service life potential. Research has shown that, for various reasons, not every bearing achieves it. Important stages which have a major impact on a bearing service life can be recognised during the bearing’s lifecycle. These stages are mounting, lubrication, alignment, basic condition monitoring and dismounting. The stages in a bearing life cycle are extremely important for achieving the maximum service life of the bearing. By applying the right maintenance practices and using the correct tools, you can considerably extend your bearing’s service life and increase plant productivity and efficiency.

Hydraulic tools for mounting and dismounting

Mounting

Medium and large SKF bearings with a tapered bore are often mounted using hydraulic equipment. SKF tools and techniques enable a controlled and precise way for SKF bearings to be mounted correctly and this helps achieve a long bearing service life. The techniques employed can also be used for other annular comments such as gear and railway wheels.

Dismounting

SKF hydraulic tools and techniques allow bearings, and similar components, on cylindrical and tapered shafts to be dismounted in a safe and controlled manner. SKF offers a comprehensive range of tools and accessories to dismount bearings and components, that enhance worker safety, and also reduce the risk of component damage.

With the SKF hydraulic mounting and dismounting techniques, you can achieve:

- More control, allowing precision, accuracy and repeatability to be maintained

- Lower risk of damaging bearings, components and shafts

- Less manual effort

- Greater operator safety

Mechanical tools for mounting and dismounting

Mounting

Small and medium size bearings are generally cold mounted. Traditional methods can cause forces to be transmitted through the rolling elements, resulting in damage to the raceways. SKF’s mechanical mounting tools help prevent bearing damage during cold mounting.

Dismounting

Choosing the right puller for the dismounting job is critical. The puller type, and its maximum withdrawal capacity are crucial for completing any dismounting job safely and easily. SKF offers a complete range of easy-to-use mechanical, hydraulic and hydraulically-assisted bearing pullers for use in many bearing applications.

Heaters for mounting and dismounting

Mounting

Incorrect methods account for 16% of premature bearing failures

SKF Induction heaters utilise advanced power electronics with application specific designs for high performance. As a result, by using an SKF induction heater, the total cost of ownership is often significantly lower. Ergonomics and safety are also an important consideration for operators.

SKF induction heaters are equipped with design features that make them easy to use and safe. Bearing support arms reduce the risk of the bearing toppling during heating, and ergonomically designed yokes help reduce operator fatigue. In addition, the remote control enables the operator to control the heater at a safe distance from the hot workpiece, enhancing operator safety.

Dismounting

SKF’s range of heating equipment enables quick and safe dismounting of cylindrical roller bearing inner rings and covers a wide range of applications. Aluminium heating rings TMBR series are designed for dismounting inner rings of small and medium-size cylindrical roller bearings. Adjustable and fixed induction heaters EAZ series are suitable for frequent dismounting of various sizes of cylindrical roller bearing inner rings.

Alignment tools

Misalignment of shafts, belt drives and chain drives is a major contributor to rotating machinery breakdowns. Accurate alignment can prevent a large number of machinery breakdowns and reduce the number of unplanned stops and loss of production. Accurate alignment can also help to extend the life time of your machines.

In today’s challenging environment of reducing costs and optimizing assets, the necessity of accurate alignment is now greater than ever.

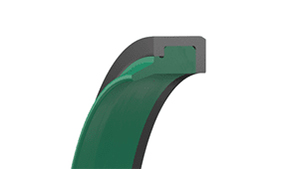

O-rings and back-up rings

O-rings are one of the most common sealing solutions. SKF supplies O-rings in a wide range of sizes and different materials, which make them appropriate for a wide variety of operating conditions and applications. They are easy to install and they enable a simple and cost-effective seal housing design.

O-rings maintain sealing contact force by radial or axial deformation in the seal housing between two machine components. The most important criteria that influence the maximum operating pressure at which O-rings in static radial sealing can be used are the following:

Dimensions and performance data are provided in the data tables:

- Extrusion gap (fig. 1)

- Material (→ Materials)

- Sealed fluid

- Temperature

Under specific conditions, there is a risk for gap extrusion (→ Extrusion gaps and back-up rings). Back-up rings prevent O-rings from gap extrusion in static radial sealing (fig. 1).

O-rings are used in a wide variety of applications sealing various media. This section focuses on sealing systems for hydraulic cylinders. Therefore, this section and provided recommendations apply to static sealing of common mineral-based hydraulic fluids (→ Hydraulic fluids).

Machined seals

SKF is the global market and technology leader in high quality custom engineered sealing solutions offering a comprehensive range of machined seals for many industries.

The innovative production system - SKF SEAL JET - reduces manufacturing and dispatch time to a minimum. Virtually any kind of seal for any conceivable application, in any dimension and design, can be produced.

SKF offers machined sealing solutions for fluid power, fluid handling and power transmission applications including special large diameter seals with a virtually unlimited diameter range.